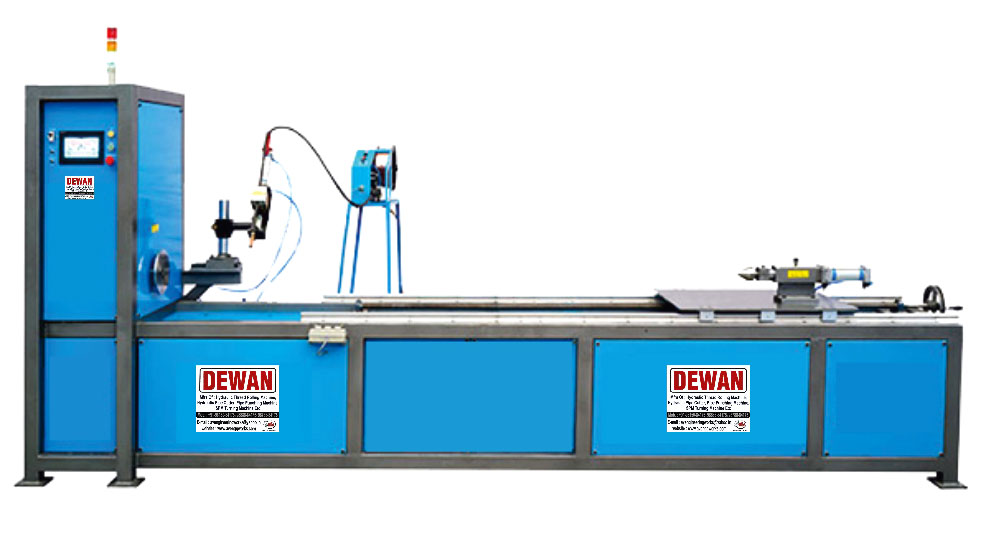

Base Jack & Inner Prop Welding M/C

TECHNICAL SPECIFICATION

Features: High production, easy to operate, easy to maintain, uniform welding results, European Design, Mig Touch from USA, Bearing of Taiwan, PLC Control System

Description: Automatic standard cuplock welding machine is used to weld six cups at time with pipe with making a tag between them on tagging fixture ,It gives high production and accuracy to product. Cuplocks are used with combination of ledger posts, base jacks to make a sctructure. All the components are used in combination of each other Base jack welding machine, inner prop welding machine, outer prop welding machine, cuplock welding machine, ringlock welding machine.

| Drive | A.C. Motor with V.F.D |

| R.P.M. | 2 to 12 |

| Motor | 0.5 H.P., 1440 R.P.M. |

| Operation | Automatic |

| Air Pressure Required | 4 to 5 Bar |

| Length Adjustment | 300 to 2800mm |

| Power | 3 Phase, 415 Volts ±5% |

| Mig Welding Power | 9 KVA Max.. |

| Frequency | 50/60 H.Z. |

| Operating Voltage | 24 Volts |

| Control | PLC With (Normal Control OR Digital Touch Screen) |

| Production | 400-450 Approx. |

| Dimensions | 14(L) X 2.8(W) X 6 (H) Feet Approx. |

| Weight | 1250 Kgs.(Approx.) |